Jaray Company Enhances Ring Die Bore Quality with German BOTEK Gun Drills and Japanese Nachi Drill Bits

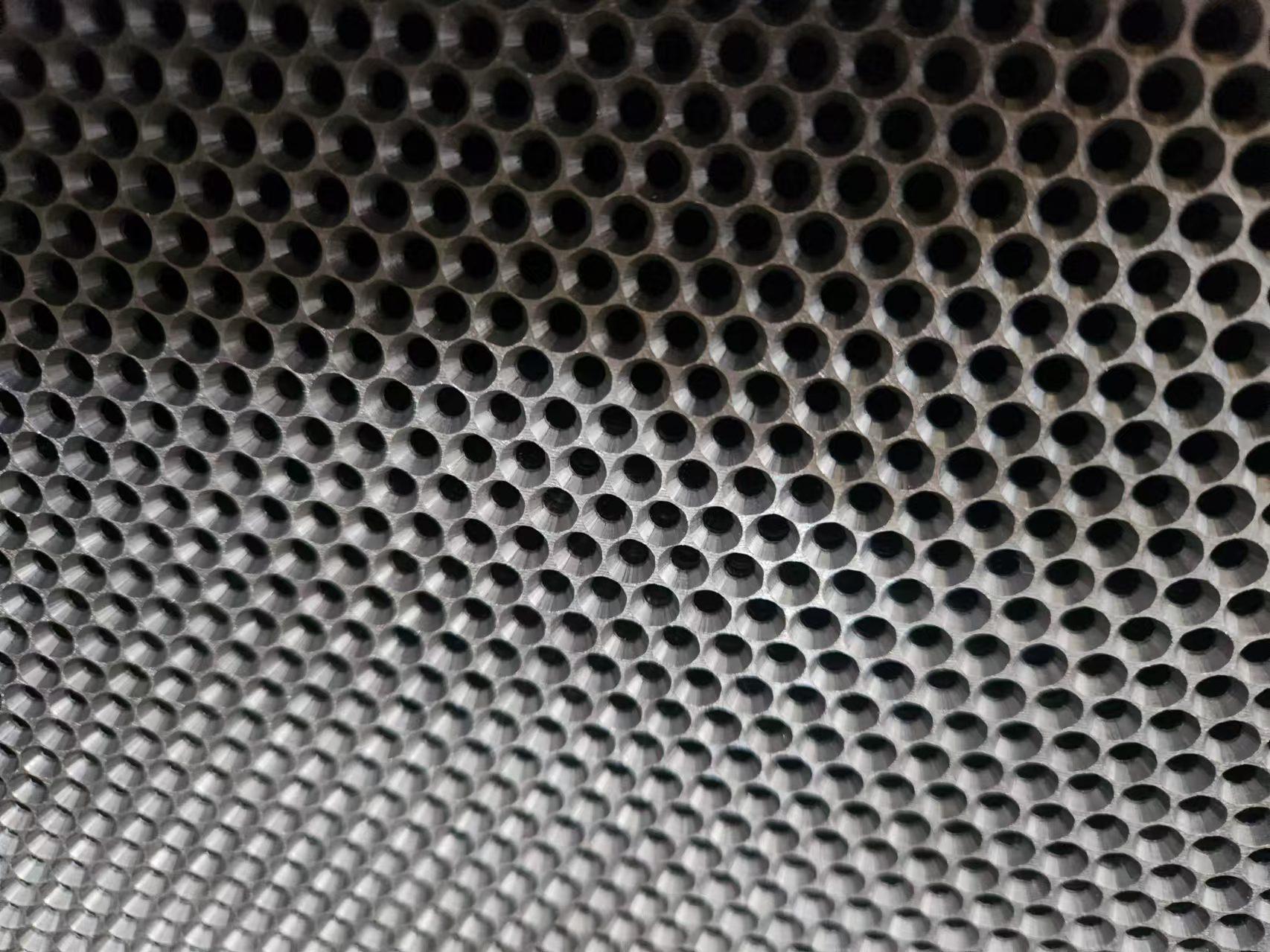

In modern machining, the precision and surface quality of ring die bores directly influence the performance and durability of the final product. To ensure the highest standards of accuracy, durability, and lifespan for their ring die products, Jaray Company has incorporated advanced gun drill technology from Germany’s BOTEK and drill bits from Japan’s Nachi. The synergy of these two cutting-edge tools not only enhances bore quality but also supports Jaray’s continuous optimization of manufacturing processes, solidifying its competitive edge in the market.

German BOTEK Gun Drills: Leaders in Precision Deep Hole Drilling

BOTEK, a renowned German manufacturer of gun drills, is known for precision machining, specifically in deep hole drilling applications, offering unparalleled stability and accuracy. By using BOTEK’s gun drills, Jaray can achieve efficient, stable deep-hole drilling, ensuring bores are within the desired tolerance range. This characteristic is crucial for ring die manufacturing, where bores must withstand high operational pressure and even minute dimensional discrepancies can impact the product’s stability and efficiency.

The BOTEK gun drill stands out for its high-efficiency chip evacuation design and durable tooling materials, allowing stable performance in large-scale production. Its advanced cooling system and chip evacuation structure prevent chip buildup within the bore, significantly reducing thermal deformation, and ensuring smoothness and dimensional accuracy of the bore.

Japanese Nachi Drill Bits: A Perfect Combination of Durability and Precision

Nachi drill bits excel in wear resistance, sharpness, and stability, making them ideal for machining hard materials under high load. Known for their hardness, Nachi drill bits can maintain sharp edges under prolonged, high-intensity use, avoiding frequent tool replacements. For Jaray’s ring die bore processing, Nachi drill bits not only ensure a high-quality bore finish but also reduce tool wear, ultimately lowering tooling costs.

In practical applications, Nachi drill bits can be selected and optimized based on the specific materials used in Jaray’s ring die, offering flexible machining solutions that ensure stability and durability even in high-stress environments.

Advanced Tooling Boosts Jaray’s Ring Die Machining Process

Integrating BOTEK gun drills and Nachi drill bits has brought notable improvements to Jaray’s ring die production process:

- High Precision Bore Machining: The combination of these tools significantly increases bore accuracy, ensuring each ring die bore meets design specifications.

- Enhanced Bore Surface Quality: With high tool hardness and stability, the bore surface is smoother, reducing wear and extending the product lifespan.

- Increased Production Efficiency: The durability of these tools reduces downtime for tool changes, thus increasing production efficiency.

- Cost Savings: Advanced tooling reduces tool wear, leading to longer tool life and lower production costs.

Conclusion

By adopting German BOTEK gun drills and Japanese Nachi drill bits, Jaray Company improves ring die bore quality while optimizing its manufacturing processes. The combination of these advanced tools not only enhances machining efficiency but also ensures high bore accuracy and surface finish, positioning Jaray as a standout in a competitive market. This innovative tooling solution has become a vital component of Jaray’s commitment to technical excellence and customer satisfaction, enabling the company to offer higher-quality ring die products.