Background

With the increasing global demand for renewable energy, biomass pellet machines are playing an increasingly vital role in the energy structures of many countries. Indonesia, a key nation in Southeast Asia, is experiencing a growing demand for biomass energy. To enhance the efficiency and quality of biomass pellet production, a renowned Indonesian company decided to procure ring dies and rollers for the Italian brand Lamec630/120 pellet machine from Jaray Mold Company.

About Jaray Mold Company

Jaray Mold Company, established in the 1990s, is a high-tech enterprise specializing in the manufacture of molds and mechanical components. Over the years, Jaray has accumulated extensive experience and technology in the field of biomass pellet machine accessories, with products exported to numerous countries and regions worldwide. The company is dedicated to providing high-quality, high-performance products to meet the diverse needs of its global customers.

Introduction to Lamec630/120 Pellet Machine

The Lamec630/120 pellet machine, launched by the renowned Italian brand Lamec, is a highly efficient biomass pellet machine widely used for pelletizing materials such as wood chips and straw. Known for its efficiency, stability, and durability, this model is a preferred choice among many biomass energy production companies.

Order Requirements

The Indonesian company placed an order with Jaray Mold Company for key components of the Lamec630/120 pellet machine—ring dies and rollers. Based on their production needs, the Indonesian company specified the following requirements:

-

Ring Die Material: High-strength alloy steel to ensure wear resistance and longevity.

-

Ring Die Dimensions: Inner and outer diameters must meet the standard specifications of the Lamec630/120 pellet machine to ensure proper machine operation.

-

Hole Diameter and Shape: Customized hole diameters and shapes based on the characteristics of different raw materials to improve pellet forming rate and density.

-

Roller Material: Made of high-wear-resistant materials to ensure long-term stable operation.

-

Roller Dimensions: Perfectly matched with the ring dies to ensure efficient operation of the pellet machine.

-

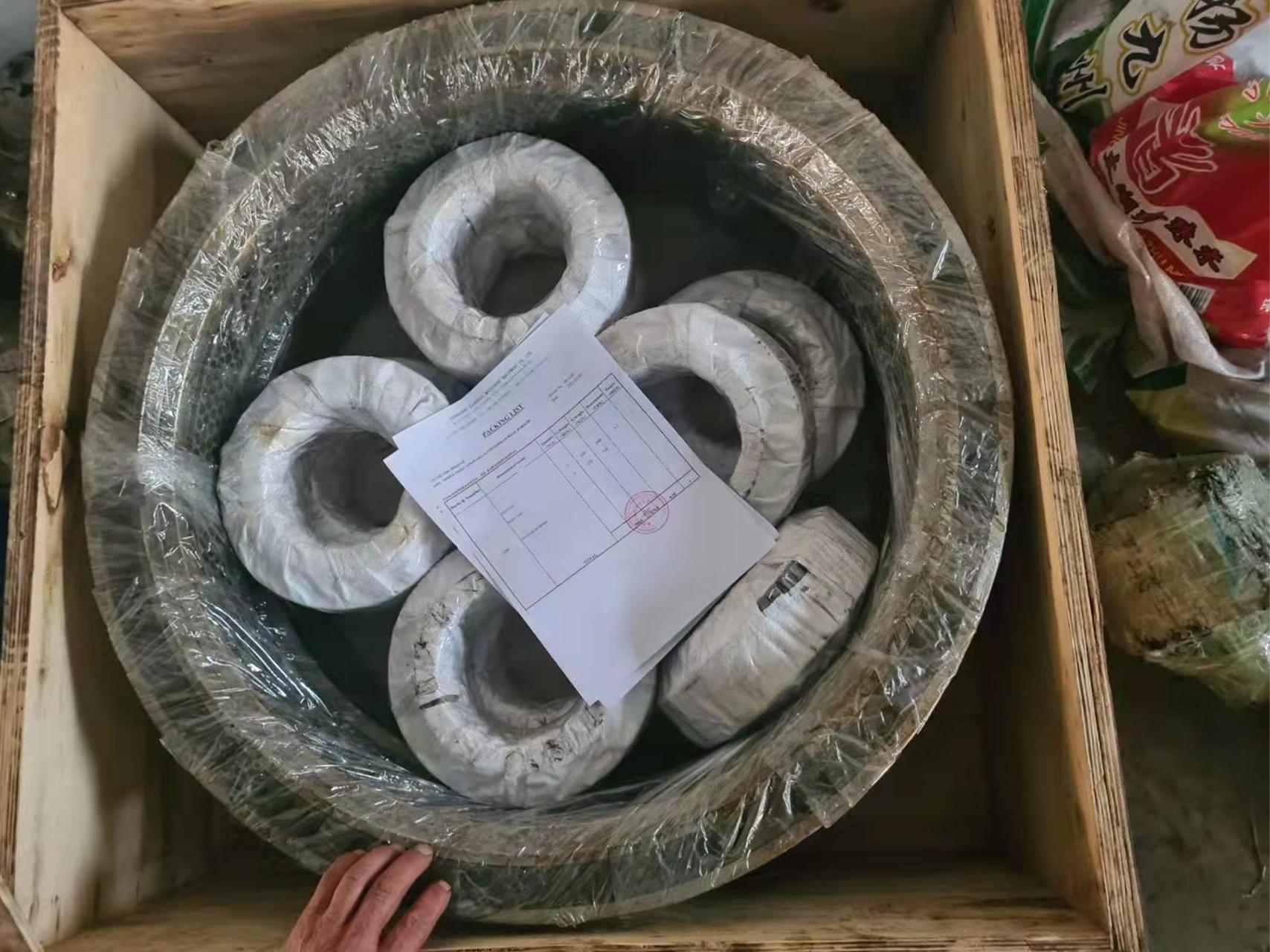

Quantity: An initial order of 100 sets of ring dies and 200 sets of rollers to meet initial production needs, with plans for additional orders based on future production requirements.

Order Execution

Upon receiving the order, Jaray Mold Company placed significant emphasis on it and engaged in detailed communications with the Indonesian company to fully understand their production needs and technical requirements. The Jaray technical team designed and manufactured the ring dies and rollers to meet the specific requirements of the Indonesian company. Throughout the manufacturing process, Jaray maintained strict quality control measures at every stage to ensure the quality and performance of the products.

Technical Support

To ensure the seamless integration of the ring dies and rollers into the production line, Jaray Mold Company provided comprehensive technical support services, including:

-

Installation and Commissioning: Sending technical personnel to the Indonesian company’s site for installation and commissioning to ensure perfect matching of the components with the equipment.

-

Operational Training: Providing detailed operational training for the Indonesian company’s technical staff, covering installation, maintenance, and care of the ring dies and rollers.

-

After-Sales Service: Offering complete after-sales service to promptly address any issues encountered during use, ensuring continuous efficient operation of the components.

Expected Outcomes

Through this collaboration, the Indonesian company expects significant improvements in the efficiency and quality of biomass pellet production, allowing them to further expand their market share in the biomass energy sector. Simultaneously, Jaray Mold Company aims to strengthen its presence in the Indonesian market through this partnership, promoting mutual benefit and a win-win outcome.

Conclusion

The sale of ring dies and rollers for the Lamec630/120 pellet machine by Jaray Mold Company to the Indonesian company marks an important milestone in their cooperation within the biomass energy sector. With joint efforts, both parties are expected to achieve their cooperation goals and drive the development of the biomass energy industry. Moving forward, they will continue to deepen their collaboration, contributing to the sustainable development of global energy.