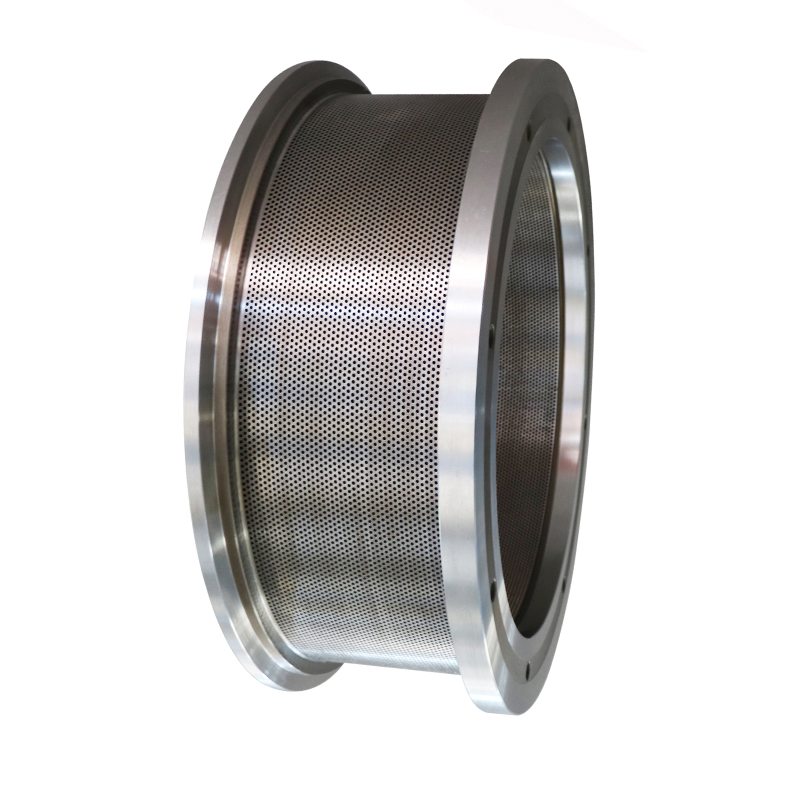

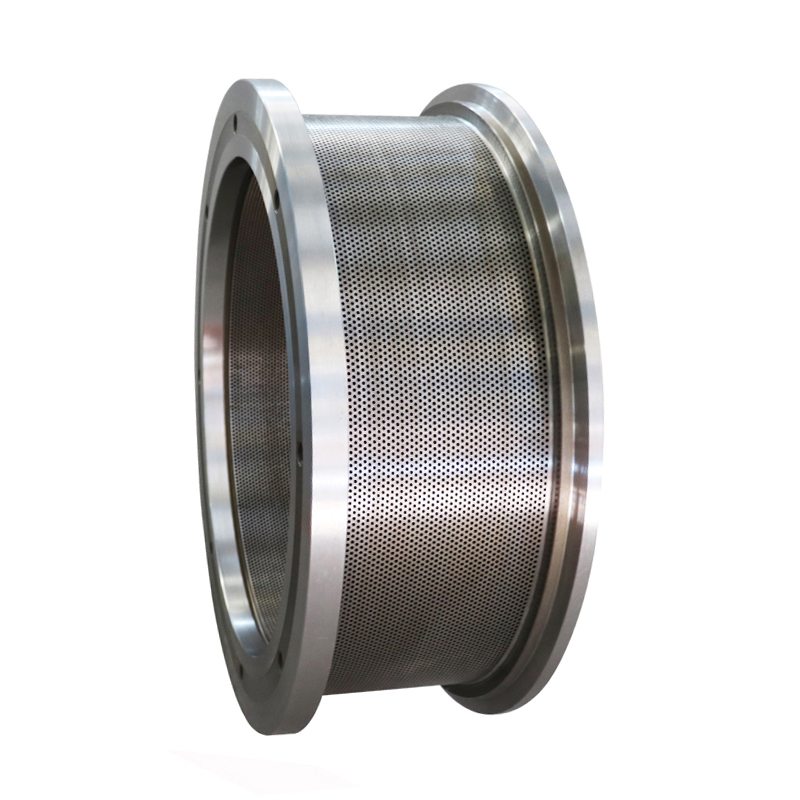

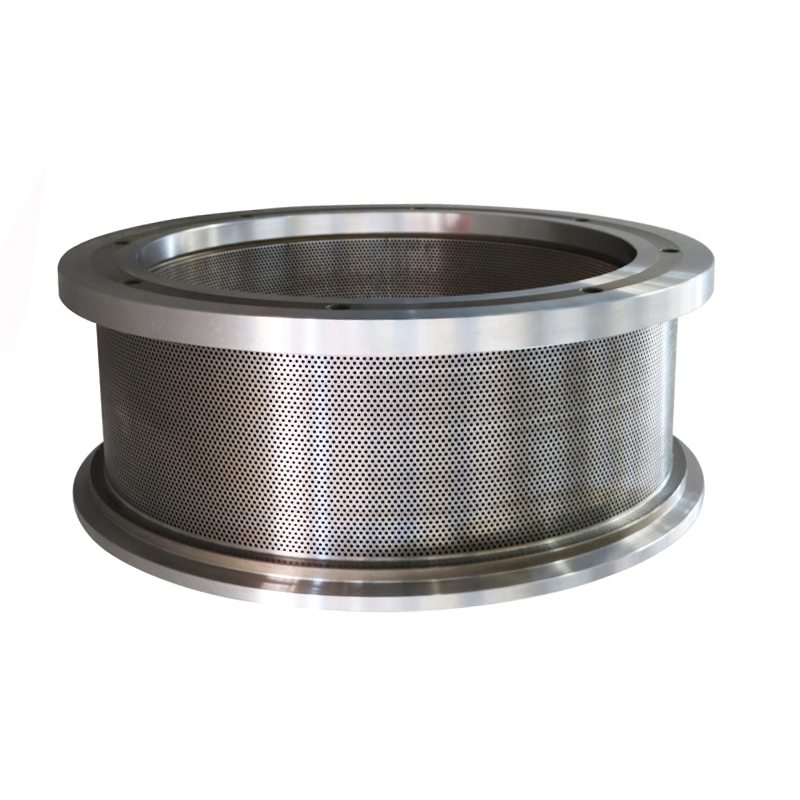

TPM series ring die

TPM pellet mill series ring die is made of high-quality alloy steel or high-chromium stainless steel (German standard X46cr13). It is processed by forging, cutting, drilling, heat treatment and other processes. Through strict production management and quality system, the hardness, die hole uniformity and die hole finish of the production ring die have reached very high quality.